Polyester Fiber

Polyester Fiber | Since 2001, there have been total 42sets 100tpd big capacity PSF lines built by Chinese companies, so among them, our group independently supplied 34 sets of complete PSF lines, occupying 54% market, and seven PSF lines were built under the cooperation of us (for supplying spinning lines) and other makers (for supplying draw lines), which occupying 16.67% market. By far, we supplied the biggest capacity PSF lines in the world, and it also owns the most PSF running lines in the world. And the typical customer Sinopec is the biggest company in China (listed at No.22 on Fortune Top Worldwide 500), and Sinopec is also the biggest Petrochemical Complex in China and owns the biggest polyester capacity in the world.

Our group started synthetic fiber machinery & equipment fabrication in the 1960’, it used to be the authorized spinning technology and machinery licensor and producer by China’s Textile Industry during the planning economy 25 years ago. It was the first Chinese company that developed 4000tpa, 7500tpa, and 15000tpa PSF line technology in the 1970’ and 1980’, and it built about 40 lines at the above capacity. It is the market occupying rate in 1990 was 100% in China.

Our group ever cooperated with Barmag in the 1980’ & 1990’ in developing SW4 series POY spinning & winder technology, and it founded the joint venture with Barmag in the middle of the 1990’ of producing SW6 & CW, SP40, and SP50 series high-speed spinning machines, and exported to Australia, Indonesia, and India. Our group has also worked with Dupont, Zimmer, and Toray for their tailor-making machine fabrication in the OEM working style. Currently, all other spinning machines produced by other companies are copied from our group technology, hence there definitely exists differences in critical technical items, especially in temperature evenness of spinning beam, polymer melt residence time/pressure control, quench airspeed, amount, pressure, flow direction uniformity control, etc., we have our own specific technology.

For long period, our group has been combining worldwide advanced technology in R&D, developing its own licensed & advanced spinning technology through combining filament & fiber spinning process advantages, the evenness of the spinning beam can be controlled within ±1’C it is really the leading technology in the world. we also independently developed our own licensed technology of radical quench, semi-open circular quench, full close circular quench, etc. This technology can form a series of spinnerets atФ238、Ф328、Ф405. And recently, our group has successfully developed bi-component PSF lines, bi-component spun-bond lines, etc.

The most selling reference in big capacity in the world

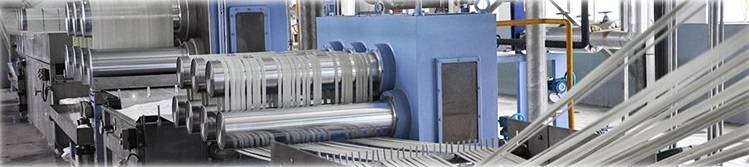

CP (CONTINUOUS POLYMERIZATION) SPINNING PSF LINE (PTA & MEG) (80~150T/D)

FLAKES RECYCLED PSF LINE – HIGH TENACITY SF & 3D- HOLLOW CONJUGATED (18~80T/D)

38. 2021 INDIA – KANCHAN INDIA LIMITED ( One of the Biggest Textile Group – BHILWARA ) 100 TPD

39. 2021 INDIA – KASHINATH TEXTILE MILLS LTD -75 TPD

40. 2021 INDIA – BADRIECO FIBER – BHOPAL 75 TPD