Diphenyl Oxide & Wire Mesh

Diphenyl Oxide & Wire Mesh | We can supply high-quality and competitive prices Diphenyl Oxide and Wire Mesh with the following specification from China:

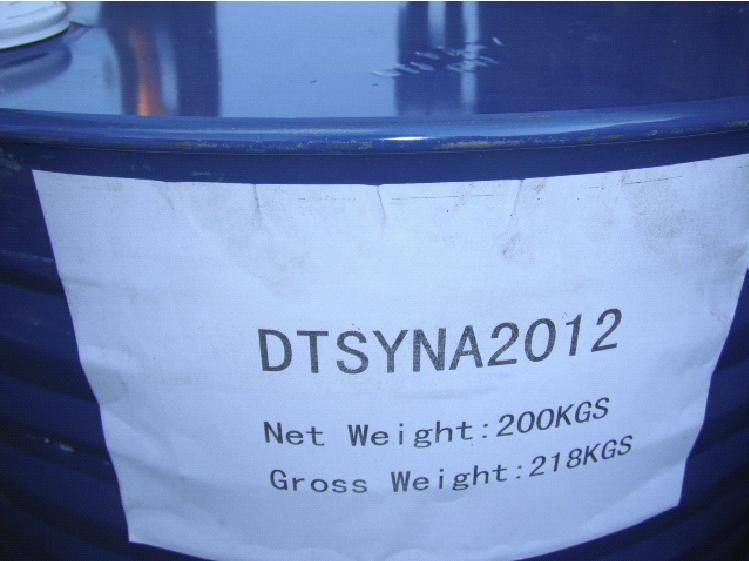

Heat Transfer Fluid | Diphenyl Oxide (DPO) + Biphenyl

| Appearance | Transparent or light yellow transparent liquid |

| Components Composition | 26.5% diphenyl, 73.5% diphenylether |

| Purity | ≥ 99.9 % |

| Crystallization point | 12℃ |

| Spontaneous ignition point | 618℃ |

| Boiling point | 257.1℃ |

| Flashpoint (closed cup) | 118℃ |

| Moisture | 0.02% |

| Kinematic viscosity(40℃) | 2.4 mm2/s |

| Density(20℃) | 1062 kg/m3 |

| Chlorine content | ≤10 ppm |

| Sulfur content | ≤10 ppm |

| Operating temperature | Liquid 12~400℃; Gas257~400℃ |

Applications Diphenyl Oxide

- Adhesives

- Calendar roll heating

- Chemicals & petrochemicals

- Distillation

- Extruding

- Fatty acid

- Fibers

- Formaldehyde

- Gas to liquid

- Gas treatment / sweetening / desulphurized

- HTF – fine chemicals

- Heat Transferred Fluid – production of bio alcohol

- HTF – production of biodiesel

- Lube oil refining

- Methyl-methyl acrylate (MMA)

- Polyester (PET)

- Refining

- Resins

- Solar CSP

- Specialty and batch chemical production

- Specialty chemicals

- Styrene

- Tall oil

- Terephthalic acid (PTA)

- Waste heat recover + orc

Key attributes

- Low Viscosity

- Precise Temperature Control

- Superb Heat Transfer Properties

- Vapor Phase Heat Transfer Fluid

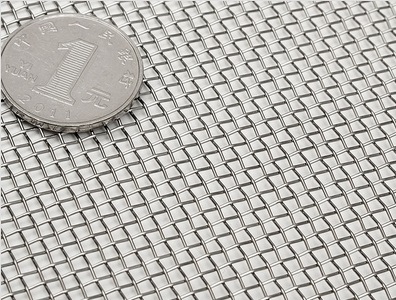

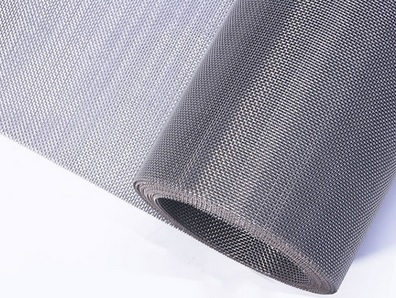

Plain Weave Wire Mesh

| Material | Stainless steel 304, 304L, 316, 316L, Brass, Copper, Bronze, Duplex Steel, Super Duplex Steel, Monel, Inconel, Harrington Alloy, Nickel Mesh, Titanium Mesh, Special Alloy, etc. |

| Type | Weave Wire Mesh |

| Wire diameter | 0.018-2.03mm |

| Hole shape | Square Hole |

| Mesh count | 2-650mesh |

| Width | 0.5m-3m or customized |

| Length | 30m/roll or customized |

Applications Wire Mesh

Wire mesh has many advantages including:

- The widest filtration range, from an aperture of more than 6 inches to a nominal 1 micron

- Open area / high flow rate

- Precision and precisely controlled aperture

- Flat; The screening surface has no sharp edges, holes, or sharp angles

- Very high-temperature tolerance (variable according to the selected metal)

- Can be used under high pressure

- Flexible – Ideal for forming concave/convex rigid shapes

- Control of chemical/acid/corrosion resistance using different metals

- Aperture special needs can be met without the high cost of tools

- High durability

- Support yourself

- Suitable as less hard media support

- Under constant stress

- The weaving process does not use any punching or drilling operations that create stress-induced weaknesses.

- Point contact only allows freer screening and reduced blindness only on the product displayed

In addition to applications in filtration and separation equipment, woven wire mesh is widely used for the following:

- Air conditioning systems

- Air filters

- Dishwasher filters

- Audio filters

- Oil filters

- Gas detection services

- Hydraulic systems

- Measuring Equipment

- Smoke detectors

- Turbines

- Making optical lenses

- Acoustic

- Distillation

- Aviation

- Chemistry

- Energy

- Solar Engineering

- Lightning protection

- Printed circuit boards

- Capacitors

- Hot gas filtration

- Catalysts

- Sugar filter

- Strengthen and strengthen

- Ventilation screening

- Microwave radio and screening

- Screen printing

- Transport belts

- Lattice front

- Plastic extrusion

- Strengthen and strengthen

- Ventilation screening

- Microwave radio and screening

- Screen printing

- Transport belts

- Lattice front

- Plastic extrusion

- Making optical lenses

There may be a few industries where wire mesh has no role to play, and with the company’s extensive experience, there are a few industries that have not been provided by Locker.