Polyester Staple Fiber (PSF) Production Line

Recycled Pet Fiber Machinery & Equipment

Comprehensive PET Bottle Fiber Manufacturing Process: From Exploration to Installation

At our group, we specialize in delivering end-to-end solutions for the PET bottle fiber manufacturing process. Our expertise spans product exploration, project design, process control, manufacturing, and installation services, ensuring a seamless start-up and running process for your production line. With a strong focus on innovation and quality, we provide a wide range of equipment and complete machinery for the polyester staple fiber (PSF) industry, catering to diverse production needs.

Our Production Capabilities

In our state-of-the-art production facilities, we offer a comprehensive range of machinery designed to meet the demands of the polyester staple fiber industry. Our equipment covers every stage of the manufacturing process, ensuring efficiency, precision, and reliability.

Spinning Line

- Melt Pipes to Can Traverse: Our spinning line is equipped with advanced technology to ensure consistent fiber quality and high production efficiency.

Drawing Line

- Tow-Creel Stand to Cutter and Baling Press: The drawing line is designed to handle high-capacity production, delivering fibers with superior strength and uniformity.

Fiber Production Specifications

We produce a wide range of polyester staple fibers to meet various industrial and commercial applications. Our fibers are available in the following deniers:

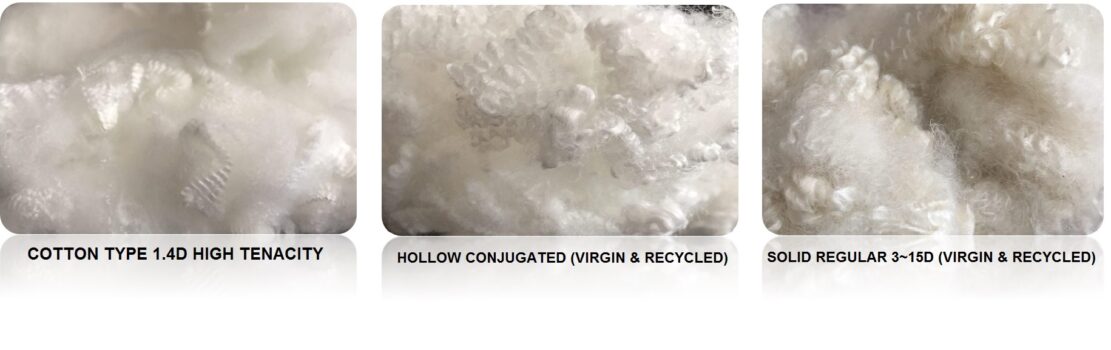

- 0.8D ~ 1.5D: Cotton type/High tenacity fibers for lightweight and durable applications.

- 2D ~ 20D: Solid regular fibers for general-purpose use.

- 6D ~ 15D: Hollow conjugated (3-dimensional) fibers for specialized applications.

Production Capacity

Our PET bottle fiber manufacturing process is highly scalable, with production capacities ranging from 25TPD (tons per day) to 200TPD. We can also customize the production capacity according to your specific requirements, ensuring flexibility and adaptability to meet market demands.

Research and Development

Innovation is at the core of our operations. Our R&D team combines global advanced technologies to develop cutting-edge solutions for the polyester staple fiber industry. We have pioneered our own licensed spinning technology by integrating the advantages of filament and fiber spinning processes. This unique approach enables us to deliver high-quality fibers with exceptional performance characteristics.

Global Leadership in PET Bottle Fiber Manufacturing

We are proud to supply the largest capacity PET bottle fiber manufacturing process in the world. With the most PSF running lines globally, we have established ourselves as a leader in the industry. Our production lines are designed to handle both recycled PET flakes and virgin chips, offering flexibility and sustainability.

Key Features of Our PSF Line

- Raw Material Flexibility: Capable of processing recycled PET flakes and virgin chips.

- Fiber Variety: Produces solid polyester staple fiber (Normal & High Tenacity) and 3-dimensional/Hollow conjugated fiber (HCF), including dope-dyed fiber.

- Denier Range: 0.8D to 20D.

- Annual Capacity: 3,000MT to 80,000MT.

PET Bottle Fiber Manufacturing Project Consulting and Engineering

We provide comprehensive consulting and engineering services to ensure the success of your fiber production project. Our services include:

- Project Design Solutions: Tailored to meet your specific requirements.

- Layout Planning: Efficient and optimized factory layouts for seamless operations.

- Technology Transfer: Sharing our expertise in recycled PET fiber production technology and know-how.

- Training Services: Designing training schemes for your workforce and offering hands-on training.

- Installation and Support: Assisting with installation, adjustment, and running of the production line.

- Raw Material Sourcing: Helping you source high-quality PET raw materials.

- Fiber Sales Support: Assisting with fiber sales upon request.

Reference List:

PET Bottle Fiber Manufacturing Process Video:

To see videos of the fiber production line:

SOME INFORMATION ABOUT POLYESTER FIBER:

Polyester is used to make many products, such as clothing, furniture, industrial fabrics, computer tapes, electrical recorders, and insulation.

Compared to traditional fabrics (such as cotton), polyester has several advantages.

ADVANTAGES OF POLYESTER:

- It does not absorb moisture, but it does absorb oil. This quality makes polyester an ideal fabric for waterproof, stain-resistant, and finally fire-resistant coatings. Its low absorption also makes it naturally stain-resistant.

- Polyester clothing can be pre-shrunk during the finishing process, and then the fabric is resistant to shrinkage without stretching and deformation.

” The Different types of Polyester Staple Fiber Machinery can be supplied by DT Int’l Group and its associates with the latest technology “

HISTORY

In 1926, E.I. Du Pont de Nemours and the American company began to study very large molecules and synthetic fibers.

The core of this initial research led by W.H. Carothers was nylon, which later became the first synthetic fiber.

Shortly afterward, in 1939-41, British research chemists became interested in du Pont’s research and conducted their research in the laboratory of the Calico Printers Association, Ltd.

This led to the production of polyester fibers called polyester in Britain.

In 1946, Du Pont bought the rights to produce these polyester fibers in the United States.

The company did further development and began selling fiber optics under the Dacron brand in 1951.

In the following years, several companies became interested in polyester fibers and produced versions of their products for various purposes.

Today there are two main types of polyester. In fact, They are PET (polyethylene terephthalate) and PCDT (poly-1,4-cyclohexane-dimethylene terephthalate).

PET is a more popular type, suitable for many purposes.

PCDT is suitable for heavy consumer applications such as curtains and upholstered furniture.